Values that inspire

The company Citrocasa "Quality - Because we can".

"To be able to produce the perfect freshly squeezed orange juice,

you have to leave conventional paths.

Only perfection down to the last detail

leads to the best result. Not an easy path, but it's worth it to us!"

Josef Pichler (Founder, Citrocasa)

Values that inspire

Everything from one source

Oranges, Juicers and PET bottles, Citrocasa always allows freshly squeezed orange juice. We guarantee 100% fully ripe, post-harvest untreated oranges for the best taste and highest juice yield, the most innovative equipment for efficient pressing and safety in juice production and everything is completed with our specially developed PET bottles, for optimal freshness and shelf life.

Our values also include our responsibility to society and the environment. As Citrocasa GmbH, we are part of the Berentzen Group. Our commitment to sustainability is therefore integrated into the sustainability activities of the corporate group. embedded. The guideline for the integration of ethical values into day-to-day business is the Code of Conduct of the Berentzen Group.

Performing Freshness

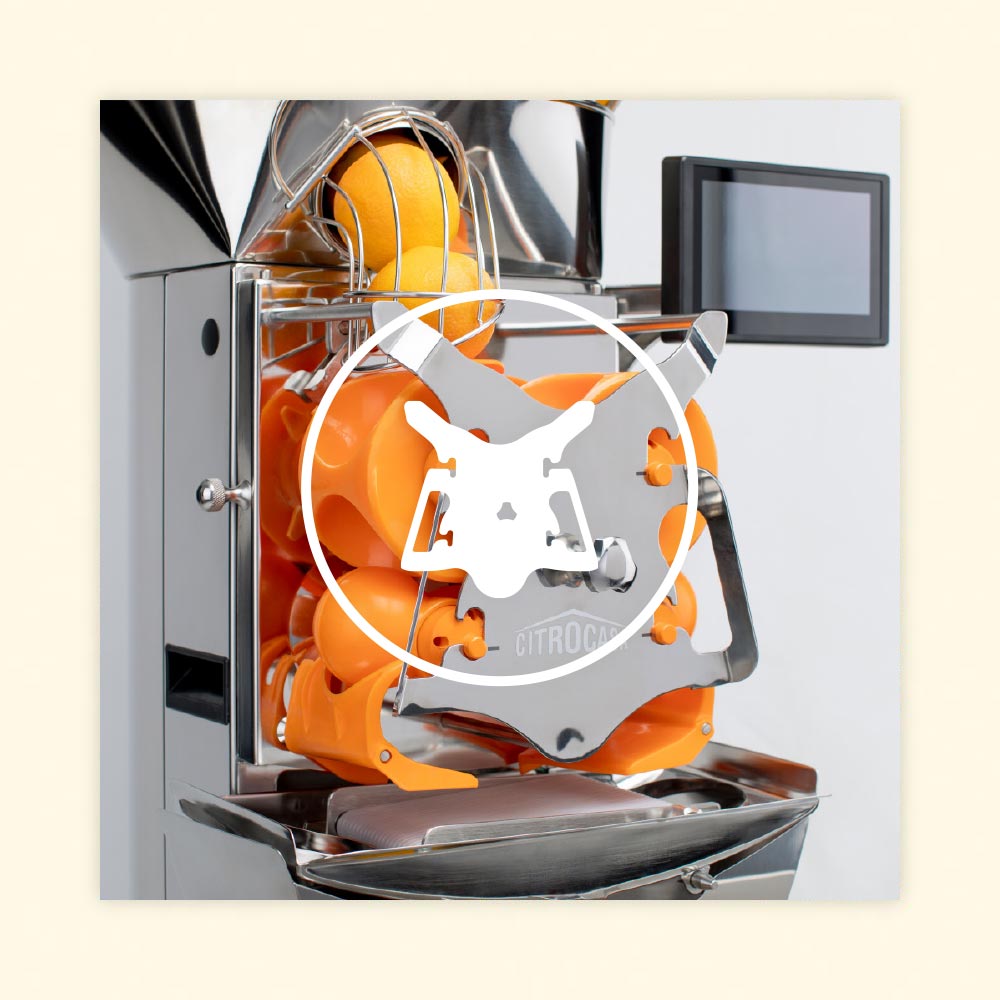

Rapid decomposition (one step) and operational safety

Highspeed cleaning in record time: ready in seconds and dishwasher safe.

In just one step, the entire pressing zone is pulled out and ready for cleaning.

Rapid disassembly in one step

Reduced cleaning effort and personnel costs

Quick disassembly and the highest operational safety

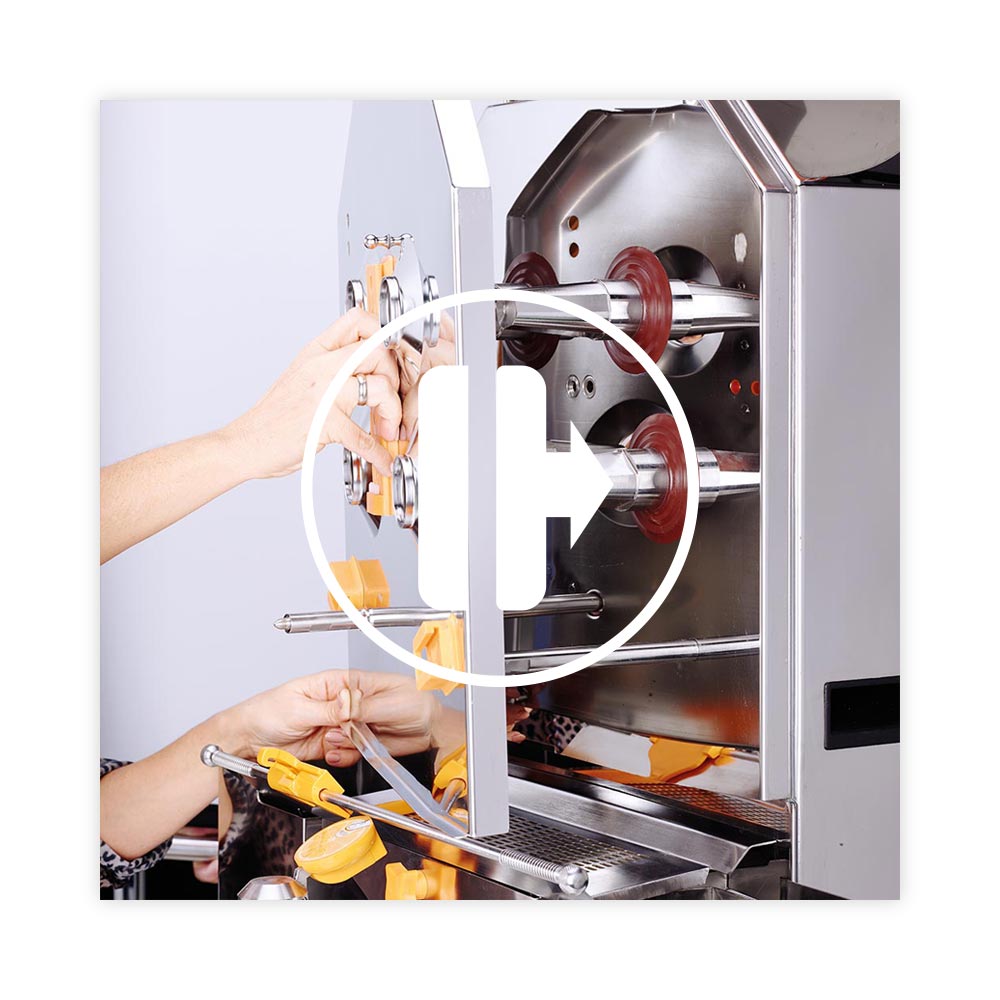

The unique Cross Holder fixes all end positions with just one screw. The pressing and cutting tools can be removed for cleaning or reinserted in seconds.

quick and easy disassembly with only one screw

Reduced cleaning effort and personnel costs

Pressing process stops automatically if machine components are loose

Time saving, hygiene and juice purity

Thanks to the ATS (Automatic Transport System) or MTS (Manual Transport System), the sieve is always clean and free of any residues (fruit flesh accumulation, seeds, peel particles). The transport system leads to maximum hygiene and juice purity with significantly reduced handling effort.

No clogging of the fruit sieve, no soiling of the machine environment

No manual cleaning of the sieve necessary

The transport system keeps the sieve free from fruit residues

Absolute flexibility

The intelligent and modular design of the Citrocasa models gives you the option of converting your existing machine from manual to automatic operation at a later date. In this way, you remain flexible and can switch between personnel and self-service at any time and at low cost.

Quick change from self-service to personal operation of the machine

No need to purchase a new machine as an upgrade to self-service

Noticeable time savings and absolute hygiene

The Double Cover is the key to 2-zone technology. By dismantling all components, including the machine rear panel (Double Cover), it is possible to guarantee absolute freedom from bacteria and germs, thus ensuring absolute hygiene and safety.

Quick and easy cleaning in the dishwasher

Reduced cleaning effort and personnel costs

Dishwashing up to 95° prevents germ and bacteria formation

Precise cutting assures ultimate juice purity

Thanks to the Citrocasa SCS Up & Down cutting system, maximum juice purity is achieved. The perfect cut of the fruit prevents the peel from tearing and thus a bitter taste of the juice. The result is maximum fruit enjoyment.

Perfect cut due to up & down movement of the cutting system

Juice is not contaminated by bitter substances and essential oils

Increased operational safety and hygiene

The programmable automatic switch-off signals when the peel waste container should be emptied. This prevents a bowl backlog and ensures absolute juice purity.

Programmable auto-stop function prevents bowl jams

no contamination of the juice due to peel jams

For absolute hygiene and durability

Citrocasa Juicers are made in all relevant zones, 100% of full stainless steel. This means the best hygiene, unparalleled product safety and excellent value retention.

Robust machine and low machine breakdown

Food-safe stainless steel design and reduced cleaning effort

Excellent value retention, service life and low component wear

2-zone technology

The 2-zone technology allows complete separation of the machine into an "Engine Zone" and "Food Zone". We comply with all health, safety and hygiene regulations in the food industry worldwide.

All components that come into contact with the juice or fruit can be cleaned in the dishwasher. Maximum time savings, highest hygiene (germ-free) and safety are thus ensured.

Engine zone

The engine zone does not come into contact with the fruit juice at any time during juicing. Therefore, cleaning is not necessary.

Food Zone

All components, including the machine rear panel (double cover), which come into contact with the fruit juice during the pressing process can be quickly and easily dismantled and washed in the dishwasher.

Smart Innovation

Innovations like our OneStep-Pressing Kit or our Double-Cover you will not find in any other juicer in the world. These unique features result in enormous time savings in the cleaning process, easy handling and component longevity. The design of the machine allows for intuitive and self-explanatory assembly.

Citrocasa

The company Citrocasa GmbH (formerly TMP GmbH) was founded in Linz, Austria, as an active distributor in the HORECA and LEH sector.

Entry into the fresh juice business with Frutas Naturales oranges and PET bottles.

The Citrocasa brand was born, based on many years of experience in the industry. Launch of the Citrocasa Classic Line.

Market launch of the CITROCASA Fantastic.

Introduction of the Citrocasa Advance Line with its unique 2-zone technology.

Citrocasa has been a subsidiary of the Berentzen Group beverage and spirits company in Germany since September 2014.

Introduction of the Citrocasa Revolution, the slimmest commercial juicer on the market.

The new ECO is aimed at all those who value independence and autonomy with the proven Fantastic - attributes.

The premium juicing standard with new displays, automatic screen cleaning, the OneStep pressing kit and individual connectivity options.